Technologies and materials

Technologies, machines and equipment

Materials processed

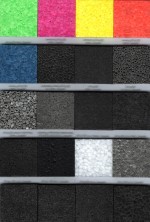

Our machines enable us to process (expand) the following materials:

- EPP (polypropylene)

- EPS (polystyrene)

- EPE (polyethylene)

- EPUR (polyurethane)

Our standard offer takes account of processing Arpro, Hanwha, Epplix.

Arpro for download: ARPRO Grades, ARPRO Safety sheet, Basic design guide, ARPRO Quality Management, ARPRO Environnemental Management

Machines and equipment

- Teubert plastic foam moulding machine (FRG)

- control system: Siemens

- steam chamber opening: 1,285 x 885 mm

- machine stroke: 1,500 mm

- max. working pressure: 4.5 bar

- cross conveyer belt

- heating carriages

- heating furnaces

- Akkaya plastic foam moulding machine

- control system: Siemens

- steam chamber opening: 1 600 x 1 200 mm

- machine stroke: 1 900 mm

- max. working pressure: 5 bar

- 5-axis machining centre

- control system: Heidenhain iTNC 530

- feed drives: digital

- working surface for a workpiece:

- working surface dimensions: 2,500 x 1,800 mm

- max. working surface load: 5,000 kg.m-2

- T-slot size: 28 H8 mm

- T-slot spacing: 340/230 mm

- longitudinal motion of the cross rail (X-axis): 2,000 mm

- transversal motion of the slide ram slide (Y-axis): 2,500 mm

- vertical motion of the spindle slide ram (Z-axis): 1,500 mm

- distance between the stands: 3,575 mm

- working feed range on X, Y and Z: 1-20,000 mm.min-1

- rapid traverses on X, Y and Z: 20,000 mm.min-1